- yuanchenwujin@hotmail.com

- +86 335 3899 615

- 中文站

Product Details

Laminated Glass Testing Equipment

Pendulum Impact Test Machine

This equipment is suitable for impact testing of various products such as toughened glass, laminated glass and other safety glass, glass curtain walls, elevator landing doors, glass doors, car walls, doorsets, architectural glass and metal guardrails, photovoltaic modules, etc.

Laminated glass testing equipment, such as 45kg shot bag impact frame, 50kg tire impact frame, 227g, 1040g and 2260g steel ball impact equipment, PVB boiling test box and Pummel testing machine for adhesion testing, etc.

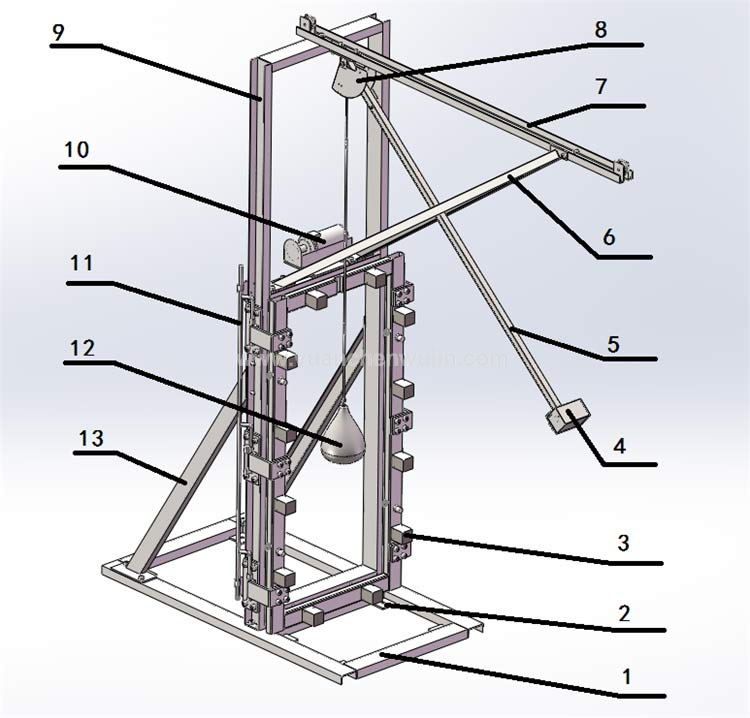

Pendulum Impact Test Machine

Pneumatic Tyres Impactor

Pneumatic Tyres Device For Pendulum Test of Glass In Building According to BS EN 12600

Reference standard:

BS EN 12600:2002

Glass in building - Pendulum test - Impact test method and classification for flat glass

Technical Parameters:

Weight 50 kg ± 0.1 kg

Tire pressure: 0.35Mpa ± 0.02Mpa

Type: 3.50-R8 4PR

Sample size: 876 mm ± 2 mm * 1938 mm ± 2 mm

Inside the sample frame: 847 mm ± 5 mm * 1910 mm ± 5 mm

Impact frame footprint: 1300 mm*3900 mm*3700 mm

Lifting mode: manual, automatic optional

Impact body release mode: manual, automatic optional

Shot Bag Impact Testing Equipment

Shot Bag:

1) Weight:45 kg 46 kg

2) Height: 330mm

3) Max diameter: 250mm

4) Lead sand size: 2.5mm

Impact Frame:

Frame Size: 1900mm*1500mm*3570mm

Samples Size: 1930mm*864mm

Lift: Electric

Release: Auto

Maximum impact height: 1200mm (customized)

Rubber Pad Width: 15mm

Rubber Pad Thickness: 3mm

Rubber Pad Hardness: Shore A50

1: Bottom Frame 2: Anchor Bolt 3: Cylinder 4: Electromagnet Release Device

5: Swing Arm 6: Upper Inclined Support 7: Cantilever 8: Scale Dial 9: Main Frame

10: Electric Hoist 11: Control Rod 12: Shot Bag Impactor 13:Lower Inclined Support

Drop Ball Test Machine

Drop Ball Impact Specimen Support and Frame for Laminated Glass

Related Standard:

ISO 3537 Road vehicles — Safety glazing materials — Mechanical tests – Clause 6: 227 g ball test, Clause 7:2260 g ball test

GB 15763.3 Safety glazing materials in building Part 3: Laminated glass – Appendix B: Drop ball impact specimen support

Principle:

Determination of whether the safety glazing material has a certain minimum strength and cohesion under impact from a small hard object

Apparatus:

Hardness steel ball:

a) 2260g, 82.5mm

b) 227g, 38 mm

c) 1040g, 63.5 mm

d) 508g, 50 mm

Frame Height: 1000mm, 5000mm, 12000mm, Customized

Automatic release and lift. Power: 220V 50Hz 580W

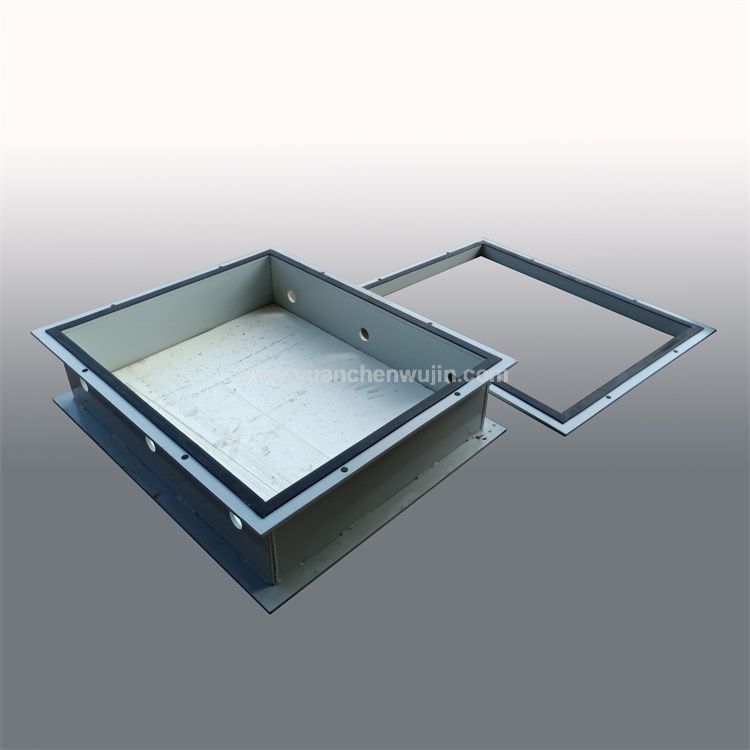

Supporting fixture:

a) Support Size: 350mm*350mm and 660mm*660mm (Customized)

b) Frame width 15mm

c) Steel box height 150mm

d) Rubber Gasket: thickness 3mm, width 15mm, hardness shore A50

e) Interposed sheet of rubber: thickness 3mm, hardness shore A50

Applied Test Pieces Size: 300mm*300mm 610mm* 610mm

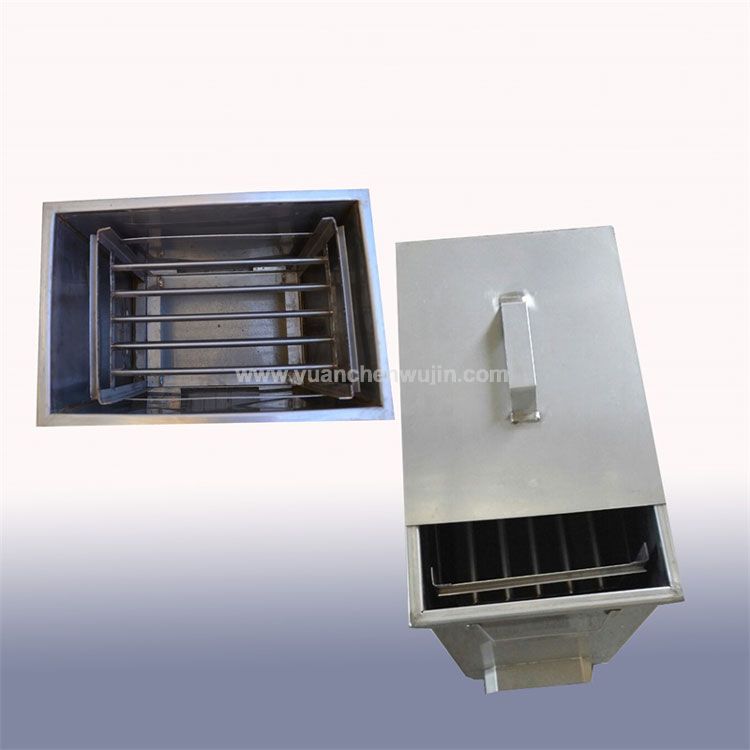

PVB boiling test box

Water bath apparatus of Boil test for safety glazing materials in Building

Laminated Glass Boiling Test Device

Reference Standard: AS/NZS 2208 Safety glazing materials in buildings

Power: 220V 50Hz 3Kw (Customized)

Outside Size: 400mm*255mm*480mm

Inside Size: 400mm*255mm*480mm

At most 6 samples with 300mm*300mm

Scope:

Determining the effect of exposure of safety glazing materials to temperature and humidity condition by boiling

Principle:

Specimens are immerse in hot water and boiling water for specified period of time and inspect bubbles and other defects

Apparatus:

The apparatus include two water baths, each of sufficient size to hold the test specimen fully immersed vertically on edge for the duration test

Samples:

Three specimen of size 300mm*300mm manufactured in a manner identical with impact test specimens and of like thickness shall be tested. These specimens may be cut from production samples of the size and thickness submitted for impact testing. Test specimen may be cut from a similar original sheet of annealed laminated glass

Procedure:

1): Immerse the specimens vertically on edge in a bath of water maintained at a temperature of 66°C ± 3°C for 3 min

2) Quickly transfer the specimens to a bath of water maintain at boiling point. Immerse the specimens vertically on edge for 2 h

3) Remove the specimens and examine for the bubbles and others defects

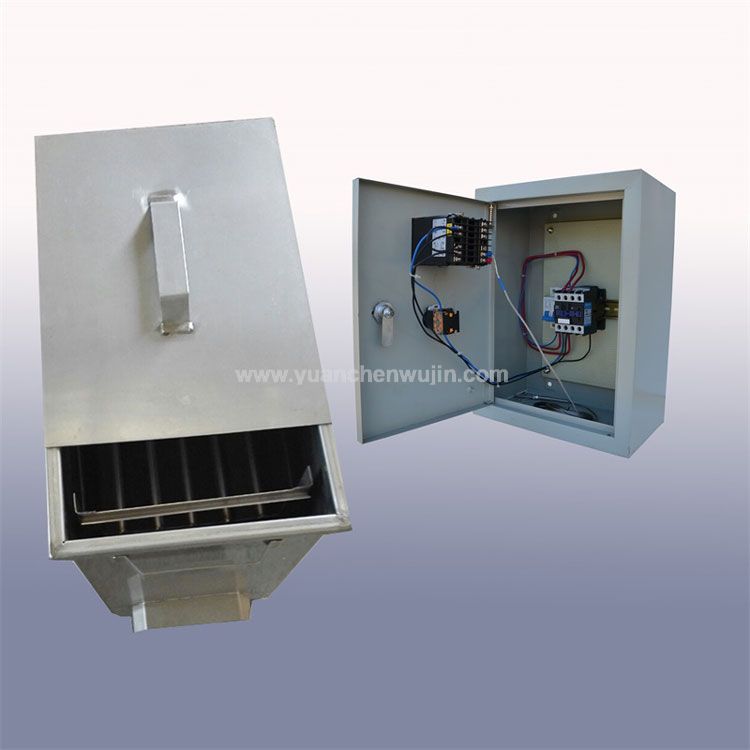

Pummel testing machine for adhesion testing

Pummel Test Equipment for Laminated Glass

Pummel Test Device

Application: Pummel test equipment for detect the adhesion of the interlayer of the laminated glass.

Data:

Hammer head diameter: 30mm

Impact Distance: Adjustable

Voltage: 380v

Whole machine voltage: 0.80KW

Test machine size: 1250 mm *1130 mm *870 mm long *wide *high

Control cabinet size: 560mm * 450mm * 1090mm long * wide * high

Knocking frequency: 220 times/min

Maximum sample size: 300 mm x 300 mm

Maximum knock size: 300 mm x 200 mm

Sample applicable thickness: 4mm-25mm